Description:

When deploying Fiber Optic networks, especially in passive optical networks (PON), optical splitters play a crucial role in distributing optical signals. Two common types of splitters used in fiber optic communication are PLC (Planar Lightwave Circuit) Optical Fiber Splitter and FBT (Fused Biconical Taper) splitters. While both serve the same purpose of splitting an optical signal into multiple outputs, they have significant differences in design, performance, and applications. Let’s explore PLC vs FBT splitter differences.

PLC Optic Splitter vs FBT Optic Splitter main differences:

| Item | PLC Optic Splitter | FBT Optic Splitter |

| Technology | Uses waveguide circuits on a silicon-based chip | Made by fusing and stretching optical fibers together |

| Splitting Ratio | Uniform splitting (e.g., 1×2, 1×4, 1×8, up to 1×64) | Typically lower ratios (e.g., 1×2, 1×4, up to 1×32) |

| Wavelength | Operates across a wide wavelength range (1260-1650 nm) | Optimized for specific wavelengths (e.g., 1310 nm, 1490 nm, 1550 nm) |

| Insertion Loss | Lower and more consistent loss | Higher loss, especially for large split ratios |

| Size & Design | Compact and suitable for high-density applications | Larger and bulkier |

| Cost | More reliable in extreme environmental conditions | Less stable in harsh environments |

| Manufacturing Process | More complex, requires semiconductor technology | Simpler and traditional manufacturing |

1. Technology and Manufacturing Process (PLC Optic Splitter vs FBT Optic Splitter)

1.1. PLC Optic Splitter: Made using planar lightwave circuit technology, PLC splitters use silica waveguide circuits to divide optical signals. They are manufactured with semiconductor technology, allowing for precise and even splitting of signals.

1.2. FBT Optic Splitter: Uses fused biconical taper technology, where multiple optical fibers are twisted, heated, and fused together. The fusion process allows for signal splitting, but the splitting ratio is fixed once the process is completed.

2. Splitting Ratio and Uniformity

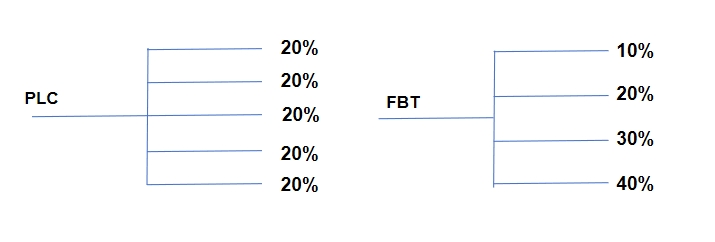

2.1. PLC Optic Splitter: Provides a highly uniform signal distribution across multiple outputs, making it ideal for large-scale networks. It supports split ratios such as 1×4, 1×8, 1×16, and up to 1×64 with consistent performance.

2.2. FBT Optic Splitter: Generally supports lower split ratios (1×2, 1×4, 1×8), and as the split ratio increases, signal uniformity decreases. It is less efficient for large-scale deployments compared to PLC splitters.

3. Wavelength Dependency (PLC vs FBT Splitter)

3.1. PLC Optic Splitter: Works efficiently across a wide range of wavelengths (1260nm to 1650nm), making it suitable for Wavelength Division Multiplexing (WDM) applications.

3.2. FBT Optic Splitter: More sensitive to wavelength variations, as it works optimally within a narrow wavelength range (typically 1310nm and 1550nm).

4. Durability and Temperature Sensitivity

4.1. PLC Optic Splitter: Has excellent environmental stability and can operate in a wide temperature range (-40°C to 85°C). It is highly durable and performs well in harsh conditions.

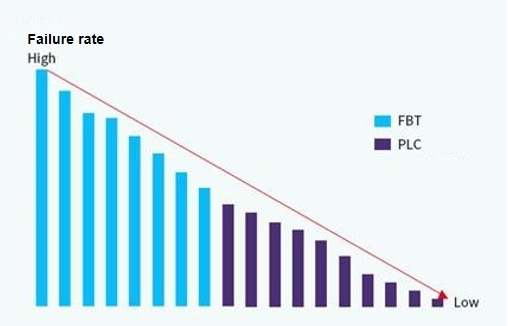

4.2. FBT Optic Splitter: More susceptible to temperature variations and may degrade over time, especially in extreme environments.

5. Cost and Application Scenarios (PLC vs FBT Splitter)

5.1. PLC Optic Splitter: Initially more expensive due to its advanced manufacturing process, but offers long-term reliability and efficiency in large-scale network deployments such as FTTH (Fiber-to-the-Home) and PON networks.

5.2. FBT Optic Splitter: More cost-effective for small-scale networks or scenarios requiring lower split ratios. It is often used in budget-conscious applications where lower performance is acceptable.

Advantages of PLC Optic Splitter:

▪ Supports higher split ratios (up to 1×64) with uniform performance.

▪ Works across a broad wavelength range, making it ideal for PON (Passive Optical Network) applications.

▪ More reliable and stable in temperature variations and outdoor environments.

▪ Compact and suitable for high-density fiber distribution.

Advantages of FBT Optic Splitter:

▪ Cost-effective for small-scale applications (1×2, 1×4, etc.).

▪ Simpler technology and manufacturing process.

▪ Suitable for specific wavelength applications where broad wavelength response is unnecessary.

Which One to Choose?

▪ For large-scale fiber networks (FTTH, PON, data centers, etc.), PLC splitters are preferred due to their high performance and reliability.

▪ For small-scale or cost-sensitive projects, FBT splitters may be a more economical choice, especially when dealing with low split ratios.

Both PLC and FBT splitters serve essential roles in optical networks, but their selection depends on the specific network requirements. PLC splitters are the preferred choice for large-scale, high-performance fiber optic networks due to their precision, durability, and wavelength flexibility. On the other hand, FBT splitters remain a viable option for cost-sensitive and smaller-scale applications.

Understanding these differences allows network engineers to choose the right splitter for optimizing fiber optic performance and efficiency.

Contact: Sales Departmment

Phone: 0086-13509605206

E-mail: info@casview.com

Whatsapp:86-13509605206

Add: 4F, B Building, Lanshang Pioneering Park, Xinfeng Rd, Longgang District, Shenzhen, China